If you use a rickshaw, you must have noticed that some rickshaws are labeled as Two Stroke engines, while some are labeled as Four Stroke.

You may have even noticed that those rickshaws 'feel differently' from each other!

Today, Shiva looks at the two stroke engine and explains how it works.

Four Stroke vs. Two Stroke

In a four stroke engine, pistons move to and fro four times in order to produce one power stroke. The first three are idle strokes (exhaust, suction, and compression) and do not produce power. To reduce the number of idle strokes, two stroke engines were invented in which complete operations, which include suction, compression, power and exhaust are all completed in two strokes only. The two stroke cycle is also known as a Clark cycle engine, named after its inventor, Mr Dugal Clark who invented it in 1880.

Working of a Two Stroke Engine

Let's take a look at the two strokes in a two stroke engine.

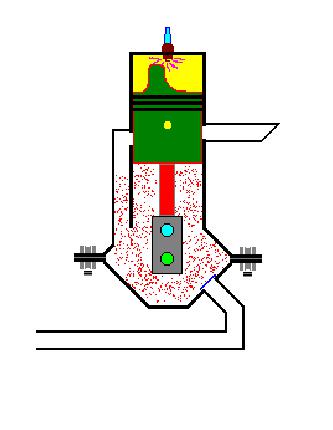

In small engines, the exhaust and inlet ports are made in the cylinder block. When a piston comes down from the Top Dead Center (TDC) to the Bottom Dead Center (BDC) during a power stroke, it opens the exhaust port. Due to this uncovering of the port, exhaust gases are allowed to escape. As the piston travels down a little more, it also uncovers the inlet port which is usually located opposite the exhaust port. Due to uncovering of the inlet port by the piston, a fresh charge comes into the cylinder.

Hence, suction and exhaust are completed in one stroke.

When a piston travels up from the BDC to TDC, it covers both, the inlet and exhaust ports and so the charge gets trapped and compressed. This is the commencement of a compression stroke. When a piston reaches the TDC, a spark is triggered from the spark plug and the charge (the mixture of air and fuel) ignites. The charge gets expanded due to rapid combustion caused by the explosion and it causes the piston to move down with force. This is known as a power stroke.

At the same time, when the piston is at the TDC, the piston skirt uncovers the port in the cylinder block from where a fresh charge goes into the crank case due to a partial vacuum created by the crank shaft and its weight. Thereafter, when the piston starts moving down in a power stroke, the charge which has come in to the crank case is pressed by crank weights to the inlet port side, ready to be taken to the cylinder. In this way, a whole cycle is completed.

Two stroke engines can be applied for both diesel and petrol fuels - though a Diesel engine does not use a spark plug for ignition, but uses the heat generated from compression itself.

Advantages of Two Stroke engines

Let's take a look at the advantages of a Two Stroke engine.

- Since the power is developed in two strokes, the engines have more uniform load as every time a piston comes down, it has a power stroke.

- Only a light weight flywheel is necessary as the engine has more uniform load.

- These engines do not have valve mechanisms and are simply designed.

- They are cheaper than four stroke engines.

- As a result of their compact engineering, these engines require lesser space.

Disadvantages:

- Efficiency is lower as some part of the heat developed during combustion escapes through the exhaust port.

- These engines are mostly air-cooled and noise from them is more than that of four stroke engines.

- Due to less time available for burning of charges, some leftover charge escapes through exhaust gases, which also causes less efficiency.

- Lubrication oil is mixed in fuel and gases burnt during combustion. This leads to higher emissions.

Conclusion

Two stroke engines are typically used only in light weight applications. Most all cars come with a four stroke engine. The reason lies mainly in the lower efficiency and the higher pollution that two stroke engines give. But, applications where smaller engines are needed, such as bikes, or machinery, often come with two stroke engines.

We will be examining the four stroke engine in more detail soon. Do let us know your questions in the meantime.